About CAM TOOLS

CAM TOOLS an ISO 9001:2008 Certified Company engaged in Precision Mould Making of plastics & Supplier of Injection Moulded Parts. We offer solutions for complex tooling challenges for many OEMs, Tier 1 and Tier 2 customers worldwide.

We take extreme pride in our team members and unlimited capabilities in all aspects of the tooling industry. From Engineering to new builds, modifications, troubleshooting of tooling issues, and engineering concerns. Our team members are highly motivated and skilled to bring you the optimum quality service you deserve. With 20 years of expertise in the tool and die industry, our dynamic team are here as your Reliable Partner for Precision Moulds & Injection Moulded Parts.

We recognize that effective Project Management is essential to conducting efficient business. Each of our Project Managers has years of practical experience in mould making and design backgrounds. They are available to provide technical support and assist in the solving of the most difficult tooling challenges. From tool launch to tool try-out, our Project Managers provide a reliable contact to ensure your commitments are met both on time and on budget.

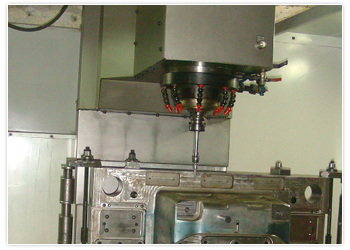

Our facility is over 7,800 sq. ft. in size and is continuously growing to meet the needs of our customers. We incorporate the latest technologies in CAD/CAM, CNC, EDM and Inspection and daily tracking procedures to reduce shop wait times and provide improved delivery dates in some cases as low as 6 weeks for rapid tools. Our technology, people and processes has allowed us to manufacture Moulds for 850 Tones Moulding Machine with benchmark delivery dates.

Looking forward to your response

We are committed for continuous development for our Mould manufacturing facilities.

Quality Policy

We, at CAM TOOLS, are committed to customer satisfaction by delivering Quality Tools and services conforming to customers need and expectations at all time.

We commit ourselves as organization and as an individual to.

DO IT RIGHT THE FIRST TIME, EVERY TIME.

We exercise Continual Improvement in our activities aiming at Higher Customer Satisfaction & Provide Required Training to our employees relevant to our activities & quality objectives.

Our Milestones

1997 - Started operations by offering CAD CAM Solutions to Various renowned Tool Rooms,

1997 - Started operations by offering CAD CAM Solutions to Various renowned Tool Rooms, 2002 - Started Mold Manufacturing Services

2002 - Started Mold Manufacturing Services 2009 - In-house Trial Facility developed by adding 225T Molding Machine

2009 - In-house Trial Facility developed by adding 225T Molding Machine 2010 - Incorporation of 5 Axis CNC Machine

2010 - Incorporation of 5 Axis CNC Machine 2011 - Expanded In-house Trial Capacity till 550T

2011 - Expanded In-house Trial Capacity till 550T

Expansion Plan for 2016 – 2018

1 Acre plot in Chakan MIDC Phase 2 allotted

1 Acre plot in Chakan MIDC Phase 2 allotted Enhancing Mold Manufacturing Capacity till 1300T

Enhancing Mold Manufacturing Capacity till 1300T Adding Double Column 3 Axis CNC Machine of 2mx1.6m

Adding Double Column 3 Axis CNC Machine of 2mx1.6m Adding 3 Axis CNC EDM Machine 2.2mx1.8ms

Adding 3 Axis CNC EDM Machine 2.2mx1.8ms Adding Die Spotting Press of 200T

Adding Die Spotting Press of 200T

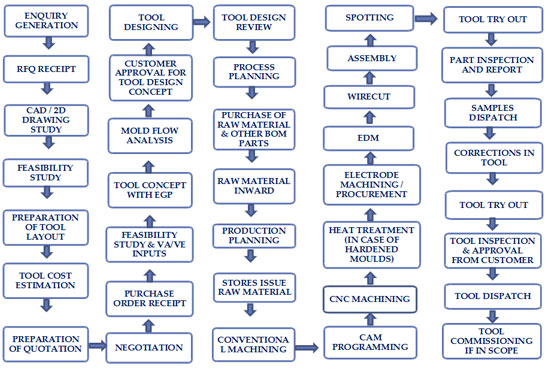

Work Flow Process